R/C Car Inertia Engine Dyno - Upgrade Kit

Couldn't load pickup availability

Estimate shipping times: 1-3 days

Use code 'WELCOME5' for discount 5% on your first order.

Free shipping and returns: On all orders over $500.

Pairs well with

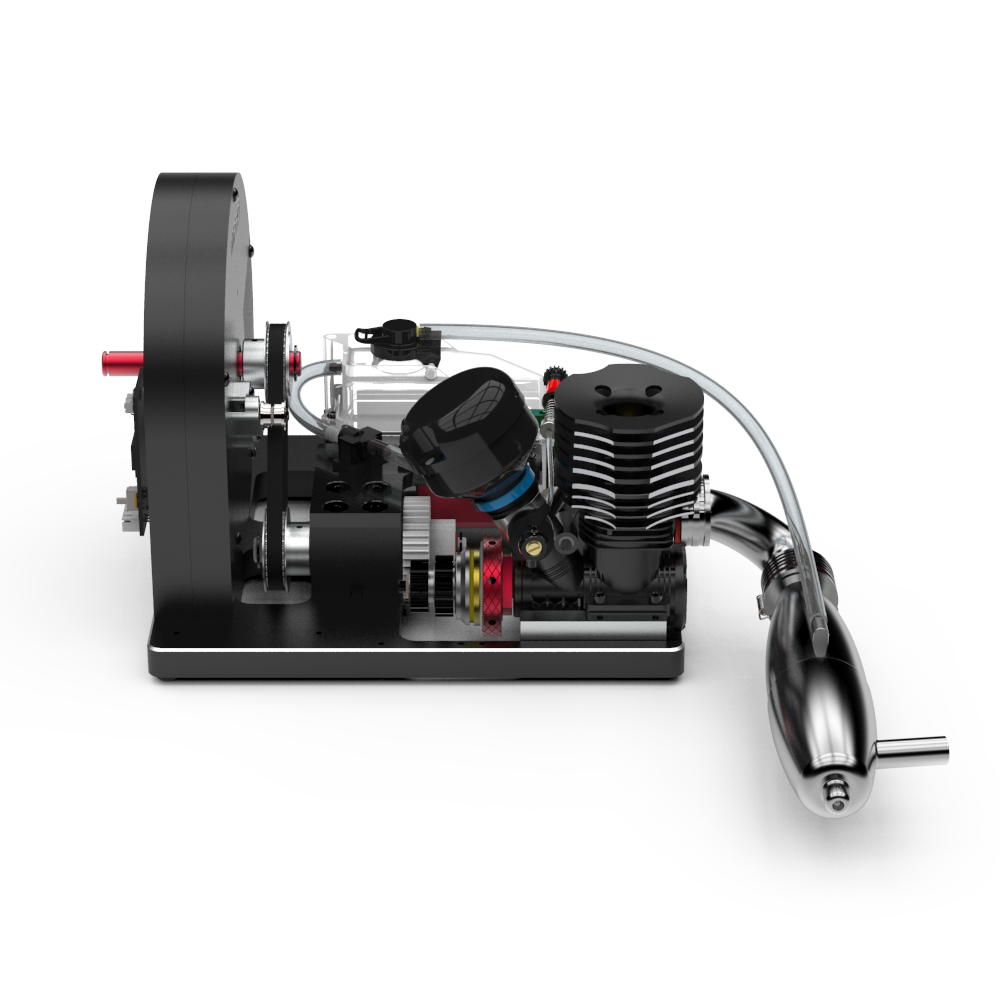

This new MINIPRO’s R/C Inertia Engine Dynamometer (Dyno) Upgrade Kit (No flywheel unit) was designed for testing nitro and gas engines. This is an essential tool for break-in, test and tune your engine to achieve maximum performance.

The load on the engine is produced by the inertia flywheel unit - a high quality 6061 aluminum frame cover around the flywheel to protect from high rpm speeds; and an embedded dyno board to accurately measure the acceleration of the DUT (device under test).

The dyno uses a pinion/gear combination to accelerate the inertial mass (flywheel). Our embedded dyno board takes the flywheel’s inertia (resistance of an object to a change in its state of motion), and measures the rate it takes to accelerate it and calculates the output power and torque of the DUT. Our dyno repeatedly measures and calculates power in small increments to produce an accurate graph on a PC of the motor’s power characteristics.

Precise, otherwise known as "Repeatability" is what you want in a dyno, that means test the same engine time after time and get the same results. Our dyno is capable of repeatable test results using the built-in Throttle controller sensor (license required) and a correction factor sensor (sold separately) to standardize the measured engine power by accounting for variations in environmental conditions like temperature, humidity, and atmospheric pressure, ensuring that power readings from different testing days can be accurately compared even if the ambient conditions are not identical; essentially, it allows you to see the "true" power of an engine regardless of the weather on the day of testing.

MEASUREMENTS:

- Engine RPM (under load)

- Flywheel RPM* (requires modification to the flywheel and an external rpm sensor)

- Dyno RPM

- Flow Sensor (for engines that produce a minimum of 40 ml/min)

- Torque

- Power-Out

- Up to three temperature readings (requires temperature sensor)

- Ambient

- Pressure

- Humidity

- Correction Factor

FEATURES:

-100cc Fuel Tank

-Digital Throttle Servo

-Manual Correction Factor (sensor required for Automatic Correction)

-Engine flywheel RPM Sensor (requires additional sensor)

-Built-in Throttle Control Sensor (license required)

-Low residual torque

-Built-in dyno controller board to measure RPM, Torque and Power.

-Built-in Aluminum base and vibration resistant.

-Low dyno losses

-Load adjustability by using different flywheels, pinions and gears.

-Low friction ceramic ball bearings

-Compact and modular design

-Low maintenance

UPGRADE KIT

This kit is for existing customers that have a motor dyno and would like to convert it to an engine dyno. A dyno controller V3.0 board is required.

SAFETY FIRST

The dyno uses a high quality 6061 aluminum frame cover around the flywheel and belt tensioner to protect from high rpm speeds produced by your engines. Retaining rings are installed around the pulleys and gear to provide extra safety. Yet we still offer the ability to see the flywheel spinning action by adding a clear window screen.

FLYWHEEL (VARIABLE LOAD)

The dyno uses the motor to simply accelerate a flywheel (variable load). We calculate the mechanical power and mechanical torque of the motor by knowing the flywheel's inertia (resistance of an object to a change in its state of motion), gear ratio and it's acceleration. We offer different sizes and materials to best suit your engine application. Additional flywheels, pinions and gears can be purchased separately. These flywheels are compatible with all our existing dynamometers; making this dyno backwards compatible.

ALUMINUM BASE

Aluminum 6061 base equipped with anti-vibration foot pads to help reduce the vibrations of your engine. This dyno is compact and easy to transport anywhere. Whether you have a electronic starter, pull-start or non-start engines, this base has enough opening to starter boxes*. A glass fiber cover is used for allowing the fuel tank and servo battery to be installed. This cover is reversible to allow your engine to be configurated per your requirements.

MODULAR DESIGN

The dyno was designed to fit different engines and exhausts configurations. You can configure the position of your engine, fuel tank, exhaust, servo deck, and dyno transmission to fit your requirements.

ENGINE MOUNTS

PINION AND GEAR SYSTEM

The dyno uses a MOD 1.0 gear transmission with one-bearing to transfer the load from the flywheel unit to the engine. This design allows the test engine to use their own clutch bell. The gear can be rotated to support 1st and 2nd gear clutch bell designs. Additional size of gears can be purchase separately.

LOW FRICTION CERAMIC BALL BEARINGS

The flywheel incorporates a set of 2 low friction ceramic ball-bearings throughout the assembly to ensure low mechanical losses and maximum efficiency.

CONTROLLER BOARD

The newest dynamometer controller V3 offers a faster processor, lower noise and newer software (V5). It features a built-in throttle control sensor (license required) and micro USB for connection for your PC. It includes one external LCD/UART port, one digital temperature port, one voltage and current sensor port, one external rpm sensor port, one flow sensor port, two analog temperature ports, one thermocouple port, and one aux port.

PRECISE TEST RESULTS

Precise, otherwise known as "Repeatability" is what you want in a dyno, that means test the engine time after time and get the same results. Our dyno is capable of repeatable test results using the built-in throttle control sensor (license required) or an the external throttle control sensor.

WINDOWS DYNO SOFTWARE

Features:

- Real-Time Data Display and Plotting

- Customizable Chart Axis

- Import/Export dyno setup profiles

- Unlimited unit settings

- Raw data storage that allows you to change settings after a test run

- Up-to four Runs on the Same Screen Graph

- Graphical Gauge Setup Options

- Logging Data

- Edit Data Live without Using 3rd Party Software such as Excel

- Save/Load Previous Runs

- Export Test Data to Excel (.csv)

- Print Test Results

- Live dyno settings option

- and much more...

WHAT IS INCLUDES?

(1) Fuel tank

(1) Digital Servo

(1) All necessary hardware.

(1) Selected motor holder

(1) MOD 1 Transmission gear

(1) Software License Key (1 PC license)

(1) Micro USB Cable

REQUIRES:

(1) Flywheel Unit with V3.0 Dyno controller *

(1) Windows 10 PC min.

(1) 6V Battery to power servo

(1) Clutch Bell with MOD 1 pinion

(1) Equipment to start your engine

IMPORTANT: A correction factor sensor is required to measure temperature, humidity and pressure during a test. You can manually input these measurements without the sensor. Starter box can be used but might require modifications to below dyno aluminum base. Throttle Control Sensor is required to control your ESC with the software. We reserve the right to change the color(s) of any component(s) of the dyno without prior notice.

* A flywheel unit includes the aluminum covers, flywheel, shield, gear, and bearings.